Road shoulder cutters (millers) SP

Drainage of the road surface by cutting of road shoulders

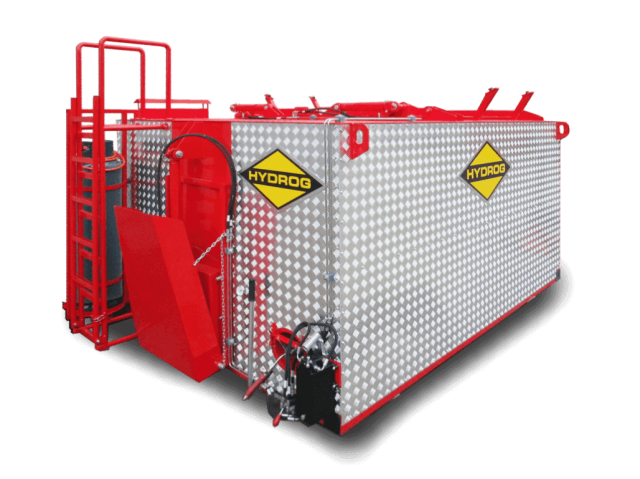

HYDROG SP-1200 road shoulder cuttter is intended for cutting and removing the road shoulders. The main purpose of using these machines is to prolong the durability of the road surface by draining water from the roadway and thus preventing damage of the road surface by the retaining and freezing water.

HYDROG SP-1200 works in conjuntion with agricultural tractor. Cutting set consists of the tractor with HYDROG SP-1200 cutter which pushes the vehicle collecting the excavated material. That might be e.g. tipper or additional tractor with trailer. Cutting auger of SP-1200 mills the ground from the road shoulder and feeds it to the conveyor through the feed rotor. The conveyor belt moves it further to the trailer or tipper box. The ejection distance is adjustable by the limiting flap and the conveyor belt speed.

Machine control is done from the cab. Rotation of auger which transports excavated material onto the conveyor belt, profiling plate, conveyor belt and width and depth adjustment are provided by power hydraulics. The hydraulic system of HYDROG SP-1200 is driven from the PTO shaft of the tractor. The hydraulic pump of the tractor is used for actuators - to change the cutting width, to avoid obstacles (trees, posts) and to move the cutting head from transport to work position.

Performance depended on several factors

The cutting width and depth are hydraulically adjustable. Cutting performance depends on road shoulder height, the desired working width, the type of soil, the cubic capacity of the tipper or truck trailers and frequency of their arrivals. Downtime can be caused by, for example, transport of excavated material to a considerable distance or insufficient number of tippers, so it is important to take care of the proper transport organization. Depending on the above parameters, the working capacity of the cutter is up to 1600 m / h and the volume of excavated material - up to 100 m3 / h.

Good dealing with obstacles

Cutting auger, feed rotor and the conveyor belt has the ability to work in "left" rotation (opposite to the working ones) – in case of blockage by large stone, etc. The hydraulic system of the cutter has an overload protection – large obstacles in soil stop the auger without damaging the machine. After manual removal of the obstacle, you can continue mechanical cutting.

The tractor must fulfill the following requirements:

power above 110 HP, the minimum speed below 300 m / h, shaft rotation: 1000 obr/min, two dual action hydraulic dividers.

| Type: | SP-1200 |

| Cutting width: | max. 1200 mm hydraulically adjustable |

| Cutting depth: | max. 120 mm hydraulically adjustable (depends on the excavated material) |

| Road shoulder slope: | hydraulically adjustable |

| Operation speed: | 200 ÷ 1600 m/h |

| Cutting tool: | cutting auger with replaceable blades |

| Drive of the cutter's components: | hydraulic from own independent hydraulic system, powered by the PTO of tractor |

| Cutting outlet: | up to 100 m3 / h |

| Transportation of the excavated material: | by conveyor belt onto tipper |

| Control: | from the tractors cab |

| Weight of the shoulder cutter without conveyor belt: | approx. 2.600 kg (depends on the type of tractor and the weight of the counterweight) |

| Weight of the conveyor belt: | approx. 650 kg (depending on tractor type) |

| Additional equipment: | cylindrical brush for sweeping the road surface behind the shoulder cutter |